- Podstawowa usługa dostosowywania

- Opieka zdrowotna

- Urządzenia i instrumenty elektroniczne

- Formy do artykułów dla matek i dzieci

- Sporty rekreacyjne

- Sztuka wyposażenia domu

- Akcesoria samochodowe

- Transport i Magazynowanie

- Oprawy oświetleniowe

- Sprzęt budowlany

- Produkt w opakowaniu

- Edukacyjne i laboratoryjne

- Odzież Akcesoria bagażowe

- Produkty do pielęgnacji i czyszczenia

- Rolnictwo i leśnictwo

- Sprzęt mechaniczny

- Artykuły dla zwierząt

- Sprzęt kuchenny

Chiny Motoryzacyjne materiały wewnętrzne Producent, dostawca, fabryka

Our Automotive interior supplies molds include: seat cover equipment, cushion products, foot pads equipment,steering wheel cover equipment, headrest equipment, hanging ornaments equipment,pillow equipment, and safety belt cover products.

Mold for Automotive interior supplies molds

NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. is a mold factory with over 10 years of experience in Automotive interior supplies molds products and equipment. We have relevant cooperation with some well-known Automotive interior supplies molds factories. In the Automotive interior supplies molds competition, our annual revenue exceeded 2 million US dollars.

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you

The services we provide are one-stop services, 1. Product design-2. 3D drawing production-3. CNC sample testing/3D printing testing-4. Mold production-5. Product production-6. Product packaging-7. Product transportation. We are a complete supply chain that can meet all the needs of our customers.

The process of customized automotive interior supplies molds product mold usually includes the following steps:

1. Demand confirmation: The design requirements of the customized car interior plastic products required to confirm with customers, including size, shape, color and material.

2. Design stage:

Product design: According to customer needs, design the appearance and structure of car interior plastic products that meet the requirements.

3. Mold design: Designed and manufactured molds for the production of the product, including the structure, size and material of the mold.

4. Mold manufacturing:

5. Processing manufacturing: According to the mold design, use processing equipment such as CNC machine tools to create various parts of the mold.

6. Assembly and debugging: assemble each component and debug to ensure the accuracy and stability of the mold.

7. Sample production: Use the production of molds to produce samples of car interior plastic products for customers to confirm.

8. Sample confirmation: Submit the sample to the customer to confirm. If necessary, modify and adjust.

9. Batch production: After the customer confirms the sample, it will produce a batch of car interior plastic products, and use the production mold for production.

10. Quality control: Make quality control during production to ensure that the product meets design requirements and customer expectations.

11. Delivery service: After completing production, deliver customized car interior plastic products to customers and provide after -sales service.

The above is the general process of customized automotive interior supplies plastic product molds. The specific process may be adjusted according to different projects and customer needs.

Automotive interior supplies molds Description

Mould Time:20-35 Days

Product time:7-15 Days

Moud precision;+/-0.01mm

Mould life;50-100 million shots

Mould cavity;One cavity, multi-cavity or same different products be made together

Mould material:P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

Runner system:Hot runner and cold runner

Base material:P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

Finish:Pitting the word, mirror finish, matte surface, striae

Standard:HASCO, DME or dependent upon

Main thechnology:Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Software:CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

Product material:ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

Quality system:ISO9001:2008

Establish time:20days

Equipment:CNC,EDM,Cutting off Machine,plastic machinery,etc

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you.We are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, we do not have a minimum order quantity, tell us your needs, we can provide you with the most professional service.

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you.

Automotive interior supplies molds making

1. Samples/Drawing &Requirement from you

2. Mould design:we will Communicate and Exchange the opinion with you after you place order.

3. Material Purchase:Steel cutting and Mould base tooling.

4. Assembling.

5. Inspection of mould : following and controlling the tooling processing.

6. Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7. Your instruction &confirmation for shipment.

8. Ready made mould before packing.

9. We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic automotive interior supplies molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory, so that we can customer any plastic and metal products for our customer.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

- View as

Wiszące ozdoby

Nasza firma koncentruje się na badaniach i produkcji niestandardowych formowania ozdób wiszących. Biegły w optymalizacji aerodynamicznej, aby zapewnić, że konstrukcja ogona spełnia stabilność i wymagania estetyczne pojazdów podczas szybkiej jazdy. Wykorzystywanie modelowania 3D i analizy CAE w celu optymalizacji usprawnionej konstrukcji, zmniejszenia odporności na wiatr i poprawy wydajności obsługi pojazdów. Wsparcie OEM i dostosowywania na rynku modyfikacji, zapewniające jednopoziomowe rozwiązanie od koncepcyjnego projektu do zawieszenia ornamentów.

Czytaj więcejWyślij zapytanieFormowanie wieszaka

Ningbo P&M Products Co., Ltd. jest dużym dostosowanym producentem i dostawcą formowania wieszaka w Chinach. Mamy wieloletnie doświadczenie w branży i jesteśmy profesjonalnymi i niezawodnymi. Przez wiele lat skupiliśmy się na dziedzinie tworzyw sztucznych do formowania wieszaka i gromadzenia bogatego doświadczenia w projektowaniu i produkcji. Zna różne potrzeby branż, takich jak logistyka, hodowla zwierząt gospodarskich, transport żywności i zarządzanie magazynem. Formowanie wieszaków o dużych wymiarach, złożonych strukturach i wysokiej wytrzymałości.

Czytaj więcejWyślij zapytanieFormowanie stojaków telefonicznych

Do formowania stojaków telefonicznych Ningbo (P&M) Plastic Metal Product Co., Ltd. ma 15 lat technologii tworzenia pleśni. To, co zapewniamy, to profesjonalna niestandardowa obsługa formy, jesteśmy profesjonalnym plastikowym producentem formy. Możemy użyć formowania wtryskowego, listwy, odlewania matrycy i formowania rotoplastycznego. Sprzęt do stoiska telefonicznego obejmuje: obudowę telefoniczną silikonową, obudowa telefoniczna TPU, obudowa telefoniczna na komputerze, skórzana obudowa telefoniczna, metalowa skrzynia telefoniczna, kryształowa skrzynia telefoniczna, wodoodporna obudowa telefoniczna, spersonalizowana obudowa telefoniczna.

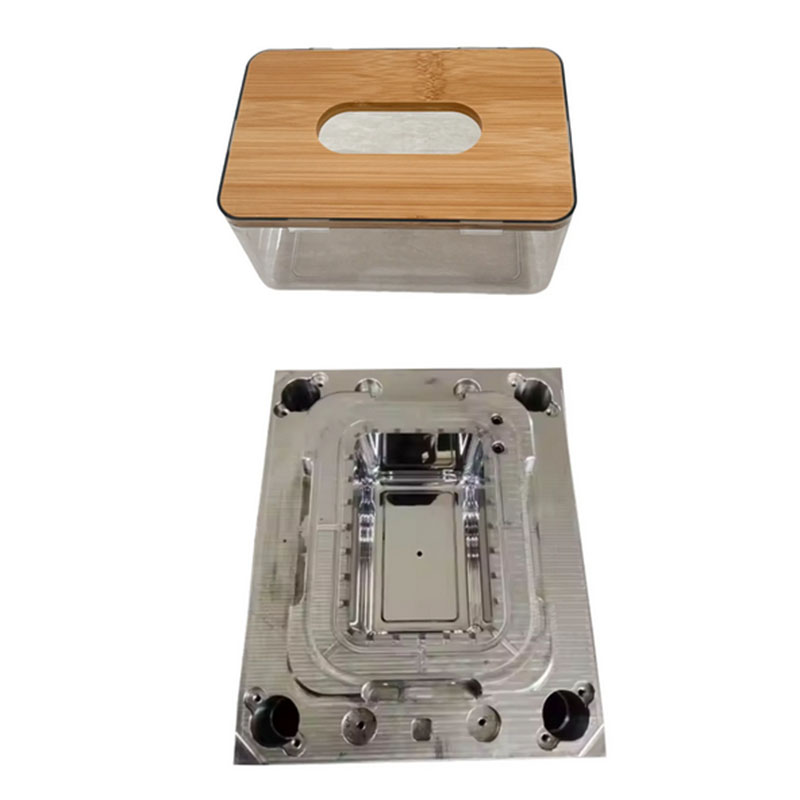

Czytaj więcejWyślij zapytanieFormowanie pudełek tkankowych

Do formowania pudełek tkankowych Ningbo (P&M) Plastic Metal Product Co., Ltd. ma 15 lat technologii tworzenia pleśni. To, co zapewniamy, to profesjonalna niestandardowa obsługa formy, jesteśmy profesjonalnym plastikowym producentem formy. Możemy użyć formowania wtryskowego, listwy, odlewania matrycy i formowania rotoplastycznego. Sprzęt tkanek obejmuje: pionowe pudełko na tkanki, pudełko na ścienne, pudełko na tkanki samochodowe, uchwyt na tkankę rolki, oprawione pudełko na tkanki. Dostosowujemy głównie i produkujemy obudowy tych maszyn, a my zapewniamy usługi produkcji tych produktów wysokiej jakości. Produkty te wymagają precyzyjnego projektowania i produkcji plastikowej formy i wysokiej jakości. Jest to ucieleśnienie naszej technologii pleśni.

Czytaj więcejWyślij zapytanieFormowanie kierownicy z tworzywa sztucznego

W przypadku tworzyw kierowniczych kierownicy samochodu, Ningbo (P&M) Plastic Metal Product Co., Ltd. ma 15 lat technologii tworzenia pleśni. To, co zapewniamy, to profesjonalna niestandardowa obsługa formy, jesteśmy profesjonalnym plastikowym producentem formy. Możemy użyć formowania wtryskowego, listwy, odlewania matrycy i formowania rotoplastycznego. Sprzęt do formowania kierownicy z tworzywa sztucznego obejmuje: standardową kierownicę, sportową kierownicę, wielofunkcyjną kierownicę, podgrzewaną kierownicę, elektrycznie regulowane kierownicy, płaskie dno kierownicy, czujnik przyspieszenia kierownicy. Dostosowujemy głównie i produkujemy obudowy tych maszyn, a także zapewniamy wysokiej jakości usługi produkcji pleśni dla tych produktów. Produkty te wymagają precyzyjnego projektowania i pro......

Czytaj więcejWyślij zapytanie